Wear and Scratch Evaluation of Surface Treated Copper Wire -NANOVEA

$ 30.00 · 4.5 (716) · In stock

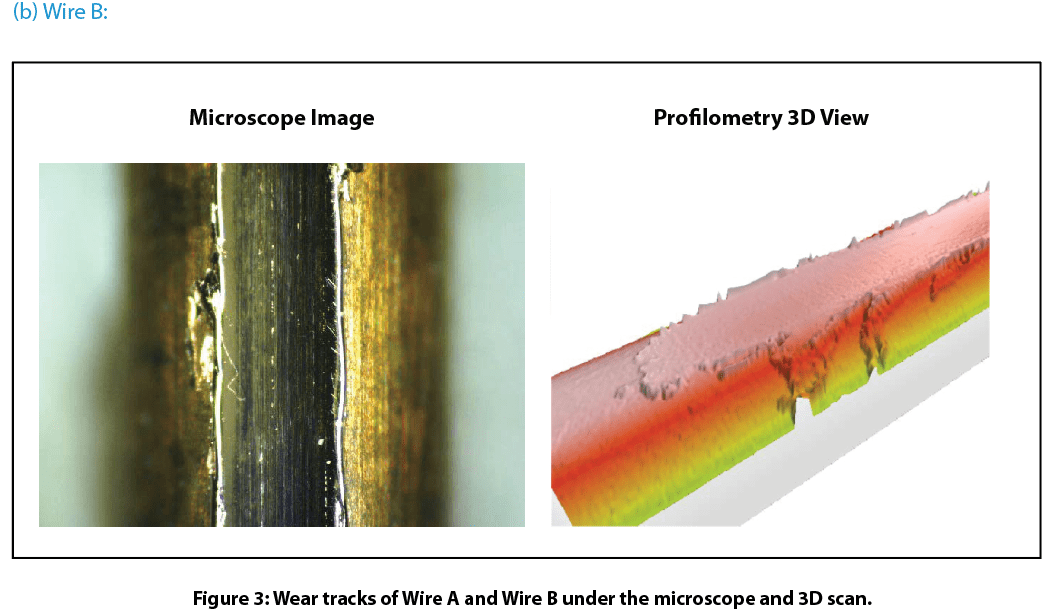

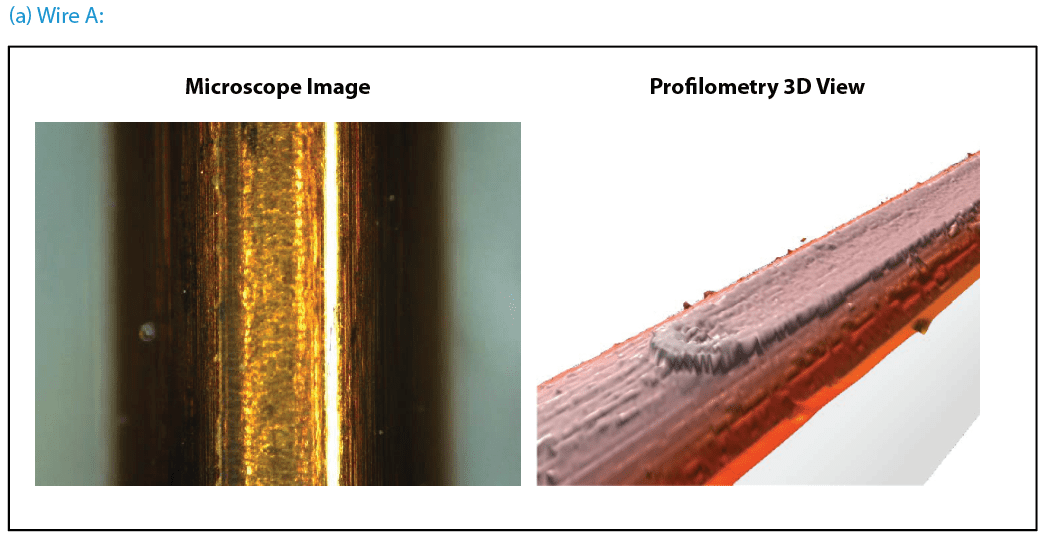

We simulate a controlled wear process of different copper wire surface treatments. Scratch testing measures the load required to cause failure on the treated surface layer.

Post-processing of additively manufactured metallic alloys – A review - ScienceDirect

Abrasion & Wear Resistance in Paint & Coatings: Basics & Test Methods

Southwire 47184730 NMWU Building Copper Electrical Wire, 14/2, Black, 98.4-ft

3D Printer Nozzle Wear: Discover the mechanisms behind nozzle abrasion

BUILDPRO MAX Slotted 4' x 3' Welding Table w/FREE Fixturing Kit

SEM image of worn surface after abrasive wear test of (a) neat epoxy

HDX Pumice Stone for Swimming Pools, Spas and other Surfaces 62665 - The Home Depot

Wear and Scratch Evaluation of Surface Treated Copper Wire -NANOVEA

They are solid brass, which means they are soft enough to cleaning or deburring with no scrach. Versatile kit & Commonly used for: Commonly used for

Brass Wire Wheel Brush Kit for Drill,Crimped Cup Brush with 1/4-Inch Shank,0.13mm True Brass Wire,Soft Enough to Cleaning or Deburring with Less

Black Oxide Coating: A Complete Guide to Precision Machined Finish

Things Engineers Should Know About Electroplating

【HAMMER】With bigger and heavier hammer head, the hammer is easier to hit. And the two ends of the hammer are detachable. We provide you 4

Punch Set Elite Tool Made of Solid Material Including Steel Punch and Hammer with Bench Block Ideal for Maintenance with Storage Case

Pet Scratch Deterrent Tape - Clear, 3-in x 90-ft, Non-Toxic, Double-Sided Adhesive for Furniture Protection

ELK Pet Scratch Deterrent Tape - Clear, 3-in x 90-ft, Non-Toxic, Double-Sided Adhesive for Furniture Protection

Ultimate Guide - Stainless Steel - Fabrication, Grinding, and Finishing with Abrasives - Empire Abrasives